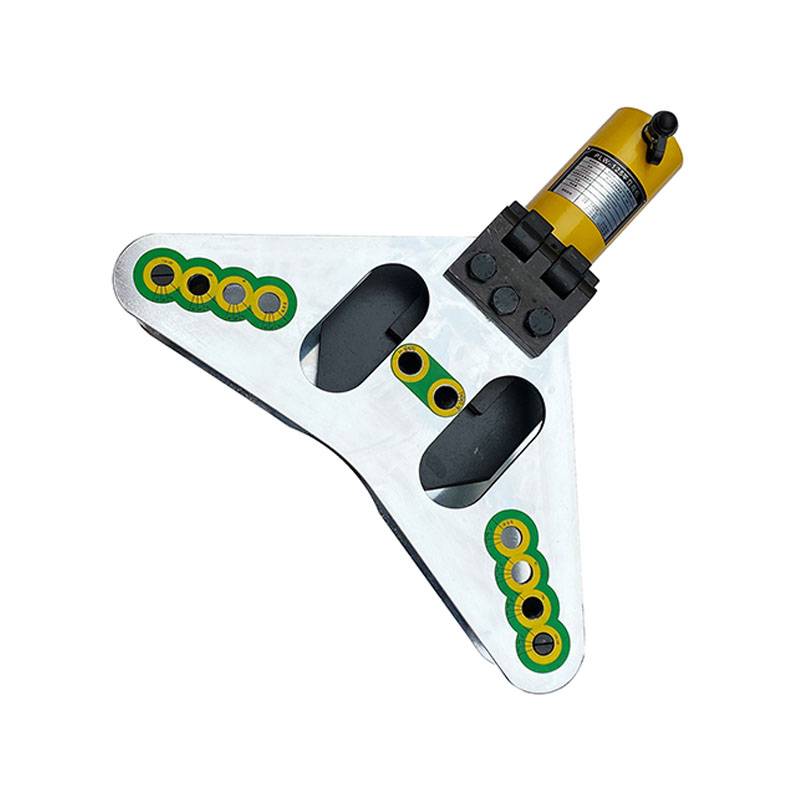

ZHH-700B-10B single oil circuit solenoid valve hydraulic electric pump 1.5KW ultra-high pressure electric pump 110V/220V/380V large oil tank plunger pump

2025.06.06

2025.06.06

Industry News

Industry News

The stability of a hydraulic pump during continuous operation is a critical factor in ensuring the reliability and efficiency of hydraulic systems across various industries. From construction equipment and manufacturing lines to agricultural and marine applications, hydraulic pumps often run for extended periods without interruption. Understanding how these pumps perform under such demanding conditions is essential for maintaining system integrity and avoiding costly downtime.

Importance of Continuous Stability

Continuous operation refers to the sustained use of a hydraulic pump over long durations, often under high loads and varying pressures. In such cases, stability means the pump can maintain consistent output, such as pressure and flow rate, without overheating, losing efficiency, or suffering internal wear that causes failure. Any fluctuations during prolonged use can compromise system performance and potentially damage connected components.

Design Features Supporting Long-Term Stability

Modern hydraulic pumps are engineered with several design features that promote stability under continuous operation. High-quality materials for internal components, such as hardened steel and wear-resistant coatings, contribute to durability. Precision engineering ensures that tolerances are tight, reducing the chances of leakage or pressure drops over time.

Some pumps feature integrated cooling systems or are designed to operate efficiently at lower temperatures. Thermal management is crucial, as overheating is one of the common causes of instability during prolonged use. Well-designed pumps also incorporate seals and bearings that can withstand the stresses of long-term operation without significant degradation.

Impact of Load and Pressure Conditions

The load and pressure requirements of the system directly affect how stable a hydraulic pump remains during continuous operation. Pumps operating near their rated capacity for extended periods are more likely to experience wear, noise, and heat buildup, all of which can contribute to instability. Selecting a pump with sufficient safety margins for pressure and flow can prevent excessive strain and extend service life.

Advanced variable displacement pumps offer more stable performance by adjusting their output according to load demand, reducing unnecessary energy consumption and mechanical stress. This adaptability helps maintain consistent system performance, especially in dynamic environments where load conditions frequently change.

Maintenance as a Key to Sustained Performance

Even the advanced hydraulic pump can falter without regular maintenance. Continuous operation accelerates the accumulation of contaminants, oil degradation, and component wear. Scheduled inspections, oil changes, filter replacements, and temperature monitoring are all essential to preserving pump stability.

Monitoring system indicators like vibration, temperature, and output pressure can help identify early signs of instability. In many industrial setups, condition monitoring systems are employed to provide real-time data, allowing for predictive maintenance rather than reactive repairs.

Environmental and Operational Considerations

The environment in which the hydraulic pump operates also influences its long-term stability. Exposure to dust, moisture, or corrosive substances can damage seals and internal parts, causing decreased performance over time. Ensuring proper housing, ventilation, and environmental protection can significantly improve the durability and stability of the pump.

Likewise, operator behavior—including how the pump is started, stopped, and adjusted—can have a cumulative impact. Gentle starts, avoiding rapid changes in pressure, and adhering to recommended operating procedures are all good practices for maintaining stability.

Conclusion

The stability of a hydraulic pump under continuous operation is not solely a function of its design but also of how it is used and maintained. When properly selected, installed, and cared for, modern hydraulic pumps can deliver reliable, stable performance even in demanding conditions. System designers and operators must consider all aspects—from materials and cooling to maintenance and environmental control—to ensure that their hydraulic systems remain efficient and dependable over time.

Español

Español русский

русский